In general, the loudspeaker coil will light up as a result of overload or if the amplifier fails and supplies DC voltage to the output. Generally, repairs are not made for low-power speakers, but for expensive high-power speakers, repair is more economical.

Tools for replacing the speaker coil;

Hobby drill or hand motor

Scissors

Soldering iron

Toluene (used as solvent, a derivative of thinner)

Solder wire

Fine-tip tweezers

Masking tape

Radiography Transparent or inch plastic card

Epoxy resin

Black contact adhesive

A fan or compressor air gun

First of all, the coil cover is removed and Toluene is applied around the cover and the cover is carefully removed with a plastic part.

Then the soldering iron and coil connections are separated and removed with the burned coil carcass. It should be careful when separating the wires, and it is useful to slightly bend them so that they do not escape.

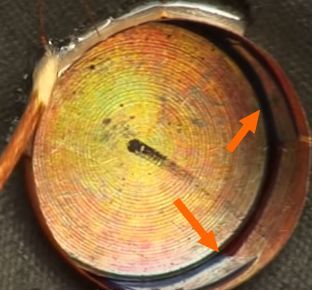

After removing the coil, the adhesive residues in the housing are cleaned by hand motor while doing this operation. In addition, dust can escape around the magnet metal inside the housing, to prevent this, you can put a piece of cloth inside and remove it at the end of the job, or you can stick paper tape on the plastic card and erase the magnet metal. Afterwards, dust and component residues are removed with a compressor.

If everything went so far, the new bonnet is assembled and the coating of the parts to be soldered is burned, cleaned and mounted to the housing.

Epoxy mixture is prepared and applied around the coil. An important detail at this stage is that the core of the bobbin needs to be centered so that you can place plastic strip pieces between the magnet metal and the crow and remove it after drying.

After drying, it is checked and soldered coil wires. Coil wires are covered with black contact adhesive.

Finally, the cover is glued and placed on a weight that does not cause collapse and left to dry. The author stated that 24 hours should be waited for the sound tests.

Speaker Coil Winding

Source:videorockola.com/tutoriales/arreglo-mantenimiento-parlantes/cambiar-bobina-parlante-altavoz/

Published: 2019/12/08 Tags: technical video

Remplacement de la bobine de réparation des haut-parleurs

En général, la bobine du haut-parleur s’allume en raison d’une surcharge ou en cas de panne de l’amplificateur et fournit une tension continue à la sortie. Généralement, les réparations ne sont pas effectuées pour les haut-parleurs de faible puissance, mais pour les haut-parleurs de haute puissance coûteux, la réparation est plus économique.

Outils pour remplacer la bobine d’enceinte;

Perceuse de loisir ou moteur à main

Les ciseaux

Fer à souder

Toluène (utilisé comme solvant, un dérivé de diluant)

Fil de soudure

Brucelles à pointe fine

Ruban de masquage

Radiographie Carte plastique transparente ou en pouces

Une résine époxy

Adhésif de contact noir

Un pistolet à air soufflé ou compresseur

Tout d’abord, le couvercle de la bobine est retiré et du toluène est appliqué autour du couvercle et le couvercle est soigneusement retiré avec une partie en plastique.