BMS 3S 25A is frequently used especially for Li-ion battery conversion of cordless drills. Its prominent features are balanced charging, over-current, short-circuit protection, allowing instantaneous 34-40A current flow, which is very good for high-power applications, and the PCB size is very small and the mosfets are cooled over the PCB. (although a heatsink may be required on the mosfets at constant high current)

However, in some cordless drills, the BMS 3S 25A module is protected on the load because of the voltage drop caused by the current draw. (this also has an effect on the performance of the batteries)

The author (@ksiman) made the following determination;

At first I logically assumed that the module had switched to protection due to the current overload, but canceling the shunt resistor of the board didn’t change anything. Then I connected the oscilloscope in recording mode to the batteries and checked the voltage on them under load. During motor operation the voltage dropped below 7V and the protection worked immediately

– Total Battery voltage 11.4V

– The internal resistance of the batteries is 66mOhm (3x22mOhm)

– Measured motor resistance 63mΩ

– Resistance of jumpers and screwdriver wrench – 23mOhm

– Resistance of the protection circuit – shunt + mosfet + connecting cables – 10mΩ

Total circuit resistance 66+63+23+10=162mΩ Current in circuit 11.4 / 0.162 \u003d 70A

But the problem is not in the current, but in the voltage drop in the batteries. At 70A current, the voltage of each battery decreases by 70*0.022=1.54V and becomes 3.8-1.54=2.26V. Here is the real reason why the discharge protection is active!

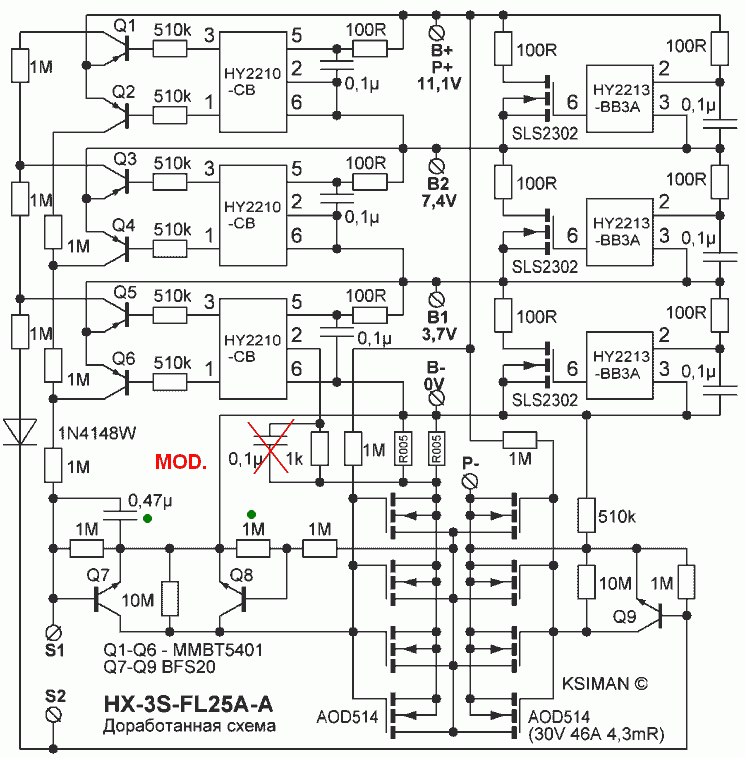

Editing or removing the protection limit reduces operating safety, so just slow down during the engine start time. A 0.47uF capacitor has been added and the discharge protection delay time is ready 🙂 if it is difficult to solder, you can solder the capacitor by mounting it on the surface between S1 and B-.

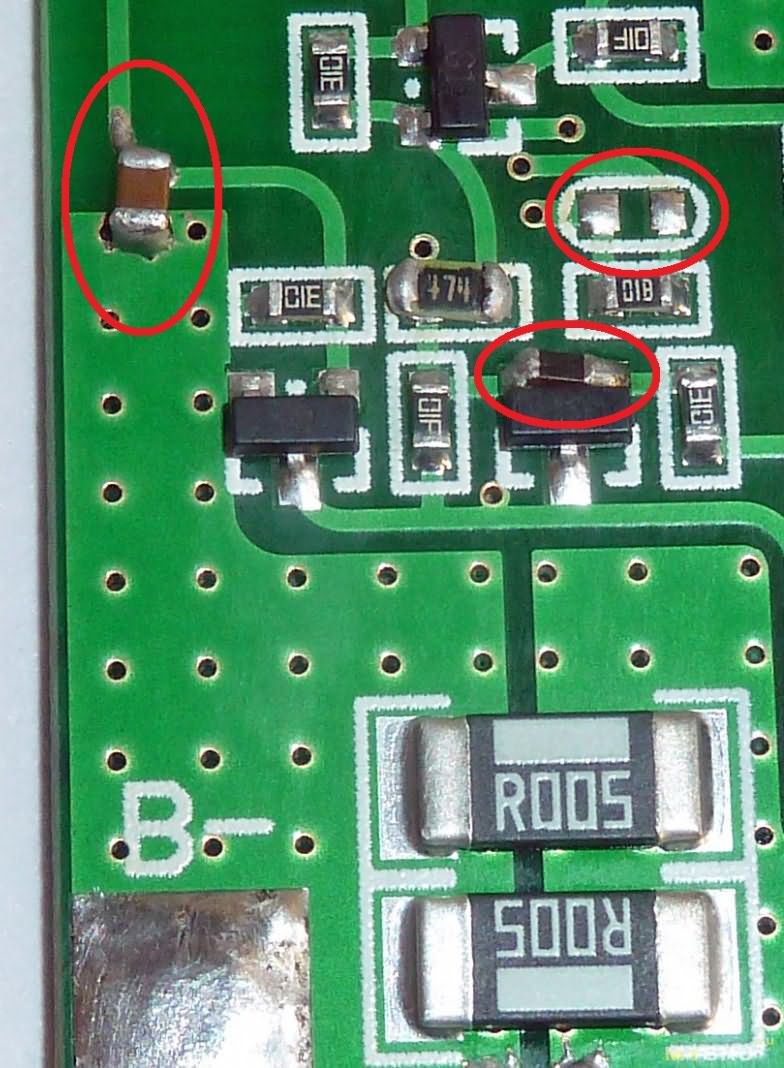

Description of all changes;

1. An unnecessary 0.1uF capacitor is soldered to the shunt from the 2 pins of the HY2210. It is not clear why they put it, there is no this capacitor in the HY2210 datasheet. This capacitor has been removed.

2. Added resistor between base and emitter to reset after shielding. Without a resistor, the automatic reset of the protection after disconnecting the load is extremely unstable, because. The smallest interference on P- interferes with resetting the protection. A suitable resistance value is between 1MΩ…3MΩ. I properly soldered this resistor directly to the terminals of the transistor. Be careful not to overheat the transistor!

3. Added 0.47uF capacitor to increase the over-discharge protection from 25ms to 300ms. Running the drill on the load no longer triggers the protection 🙂

Modified on PCB

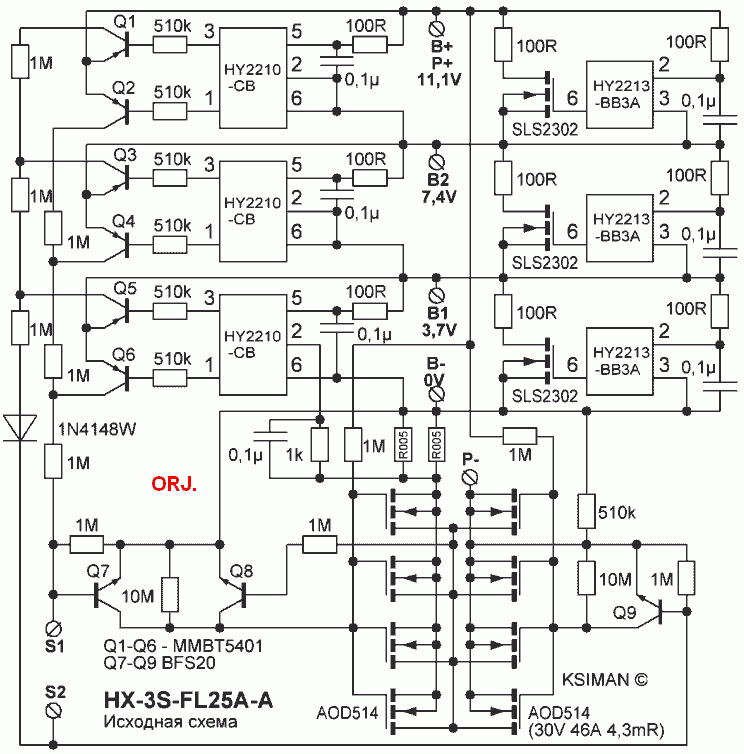

Original and Modified BMS 3S 25A Circuit Diagram

Note: 5A 70 degree thermal fuse is optional. If possible, it would be good to use it for protection and security.

Source: mysku.club/blog/aliexpress/55176.html

Published: 2022/10/07 Tags: battery charger circuit, power electronic projects

how about bms 4s? have same problem

check your 4s board it might be similar

Great effort you have done and solved a common problem. first of all Thank you a lot for this effort. you have used 0.47uF capacitor to increase the over-discharge protection from 25ms to 300ms.

Now please suggest me if I want to decrease the over-discharge protection from 25ms to 1000ms which capacitor will used. Thanks again.