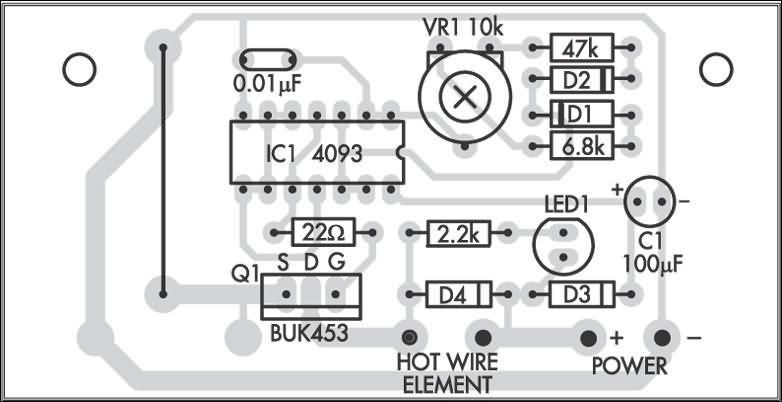

Foam Sponge Cutting Machine is based on HCF4093 (CD4093 can be used instead). By heating the resistance wire, which is connected to the mechanical part with the circuit, it ensures that materials such as sponge and foam are cut properly. With the VR1 potentiometer, temperature adjustment of the resistance wire can be made.

BUK453 mosfet is used in HCF4093 output. The operating voltage of the circuit is 12V DC, you may need to use a high current power supply according to the temperature of the wire. If you cannot find a 1N914 diode, you can use 1N4148 instead.

In fact, the control circuit is not different from other PWM driver circuits, that is, it is not a circuit specific to the foam cutting machine. circuits can be used.

In the cutting process, there is no need to heat the wire until it turns red, so you can use chrome nickel resistance wire with high resistance.

Hot Wire Cutter

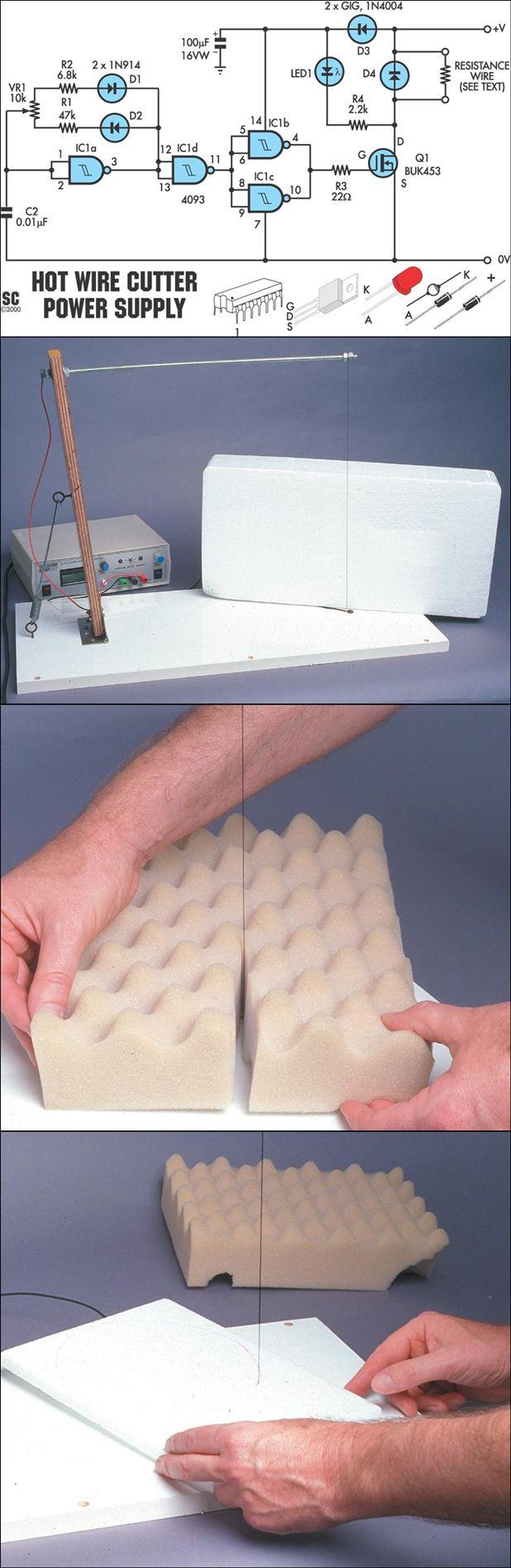

It is easy to make and allows you to cut the plastic foam without falling apart. Many people have a need to cut expanded polystyrene foam (you probably know it as “styrofoam” or “coolite”), foam rubber (not actually rubber!), and many other soft plastic materials.

They often resort to using a Stanley knife, handsaw, band saw, jigsaw or even an electric carving knife. . . and the result is often a lot of mess for too few cuts!

The ideal way to shape this material is to use a hot wire cutter. Actually, that’s a bit of a misnomer. It should be called a hot wire melter because that’s what it does – but they’re always called hot wire cutters, so we’ll stick to that name.

Ok, it’s not very pretty, but it works! We found a skirting board from an old kitchen cabinet, a spring from an old bed, screw eyes and a hinge from a scrap bin… We’re sure you got it. Here we are about to cut this thick polystyrene foam block in just a second. The result: a beautiful, clean, straight cut with no mess!

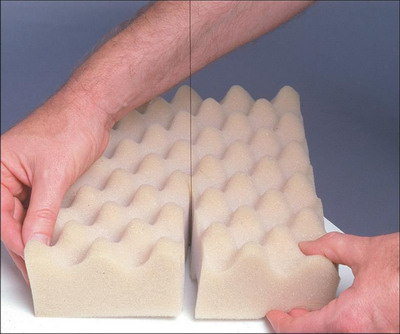

The cutter will go through most types of soft plastic just like a hot knife through butter (same principle actually) and the result is a very smooth cut with no residue to be swept away later. You can also make the most complex cuts that are impossible with any other method. And the cuts can be angled.

You can also cut very thick materials. Our prototype cutter can easily cut foam thicker than 400mm and it’s not difficult to make a much larger one if you wish.

A hot wire cutter is made from a resistance wire that is held taut and heated to just below red heat. At this temperature you can feed the material slowly and you will get a very smooth cut.

As you can see from the photos, we made our hot wire cutter from various materials we found in the place. The skirting board is made of Laminex coated chipboard leftover from a kitchen installation.

The vertical member was made from a scrap of 16mm Formply, while the horizontal 5/16″ threaded rod came from a cable reel. The hinge, screw eyes, spring and other parts were also removed from the scrap bin.

The important thing to note about this project is that it doesn’t have to look good; it just needs to work.

For example, we could use some raw chipboard for the base and a piece of hardwood decking for the vertical member. Or we could use a 3mm steel belt bent at right angles and hinged at the base to carry the vertical cutter wire.

Sponge Foam Cutting Machine Circuit Diagram

Source: http://www.siliconchip.com.au/cms/A_102846/article.html

Published: 2008/09/04 Tags: analog circuits projects, simple circuit projects

BA1404 Stereo 3V FM Transmitter Circuit

Circuit based on BA1404 FM Transmitter works with two AA batteries can be connected if desired 6 volt dc adapter antenna output RCA Input SKET are 300 and 75

Frequency range: 95-105mhz (extended with material changes;)

Transmission range: 40m folded dipole antenna with the transmitter

BA1404 Current consumption: 10mA

Corruption: 200mV audio signal level is typically 3%

Typically 45dB at 1kHz: Separation between channels