For this Timer circuit, there is information about the operation of the system, how to use a circuit designed for the car called “Adaptive Turbo Timer”, but in English 🙂 still, the source codes are pcb and so on. Since it has drawings, it can give inspiration for different projects that are worth sharing.

Adaptive turbo timer If your vehicle’s turbocharger is just starting, it is vital that the engine idles for a few minutes before shutting down. This Adaptive Turbo Timer does the job automatically. It only works when needed and adjusts the idle time based on how hard you drive.

For most turbocharged cars, having to let the engine idle for a short time before turning it off is often impractical.

Another problem is that in many cases this is not really necessary. Your journey may have been rather slow and the turbo didn’t run out. Or on brisk rides, the turbo may be running, but not in the last few minutes. Other times, while the turbo is still in use, the engine needs to idle to cool.

Why do automakers recommend this idle time? It’s all about extending the life of the turbocharger and especially its bearings. Turning off the engine immediately after the turbo starts means that the turbo will still spin because it is running at very high speeds. This also means that the bearings will pass through the engine without fresh circulation oils. Any residual bearing oil will overheat and burn or darken from very high turbo temperatures.

If this happens repeatedly, the result will be premature bearing wear. Conversely, idling the engine for a while before turning it off will retain lubrication until the turbo cools.

Unless you’re installing a turbo timer, you’ll have to make a decision to idle the engine or just stop when parked. However, most turbo timers will always idle before shutting down the engine, regardless of whether it is necessary or not.

Our new Adaptive Turbo Timer differs in that it decides whether to provide a cool-down time and if so for how long. Their decisions are based on the vehicle’s recent driving history. If the turbo has not been used for the last 15 minutes, for example, no cool-down time will be provided. On the other hand, if the turbo has been active in the last few minutes, the engine will idle for proper turbo cooling.

How does he know?

So how does the Adaptive Turbo Timer monitor the latest driving history and change the cool-down time accordingly? It does this by monitoring a motor sensor connected to the load. Typically, this will be an airflow sensor, a Manifold Absolute Pressure (MAP) sensor, an oxygen sensor, a throttle position sensor, or a temperature sensor. Only one sensor is required to provide this engine information.

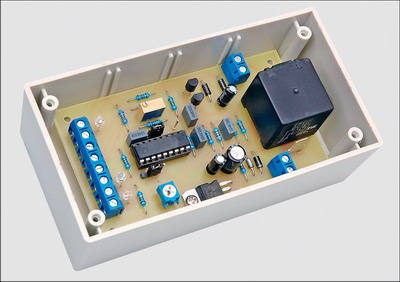

Timer Circuit

https://320volt.com/wp-content/uploads/2008/09/16f628-timer.jpg

Source: http://www.siliconchip.com.au/cms/A_109072/article.html Timer Circuit schematic pcb PIC16F88 pic assembly source code alternative link:

Şifre-Pass: 320volt.com

Publication date: 2008/09/01 Tags: microchip projects, microcontroller projects, pic16f88 projects

Backup Battery Control Circuit

L4949 for control, integrated 4093B is being used check the status of the main battery and the backup battery is required in case 80 amp relay is activated – Control Circuit for Replacement Battery with L4949 4093B

Backup Battery Circuit